Kikuo Hayakawa, NOST Tokyo

Origineel gepubliceerd op de site van Agentschap NL.

Gebaseerd op de hoeveelheid calorieën die Japanners dagelijks via hun voedsel binnenkrijgen is slechts 39 procent afkomstig uit Japan. De rest moet geïmporteerd worden uit vaak veraf gelegen landen. Daardoor is er een grote afstand tussen leveranciers en klanten.

De logistieke kosten van de voedseltoeleveringsketen in Japan bedragen 8,46 procent van de totale kosten. Vergeleken met andere voedselproducerende landen zijn deze kosten hoog. Japan werkt daarom hard aan technologieën die deze kosten omlaag kunnen brengen zonder de kwaliteit en veiligheid van voedingsproducten in gevaar te brengen en de hoeveelheid overtollig voedsel te groter te maken.

Tijdens het Food Technology Forum in Tokio, in juni dit jaar, werden veelbelovende technologieën getoond, zoals het Ice Battery systeem, de antivibratiecontainers voor groenten en fruit, het anti-spruitsysteem voor aardappelen en de niet-destructieve monitoring van de kwaliteit van vlees. Al deze systemen kunnen de logistiek in de toeleveringsketen van voedingsproducten verbeteren en de kosten verlagen.

Details:

Since Japan joined the future free trade agreement negotiations called Trans-Pacific Partnership (TPP) in July 2013, the Japanese food industry needs to change its existing business models including logistics because it is still expensive. In Japan the logistics cost of foods accounts for 8.46 percent, which is the highest ratio compared to other manufacturing industries in Japan.(1) At the Food Technology Forum in Tokyo, June 2013, organized by Japanese Society of Agricultural Machinery, the latest developments in food logistics are reported and with emphasis on new technologies to reduce the logistics cost of foods while maintaining or improving the food quality and safety and minimizing food loss. Promising technologies like the IceBattery system, shock absorbing packages for fruit and vegetables, prevention of sprouting potatoes and meat quality check by LED, were introduced as improvements of food logistics in the near future.(2)

IceBattery

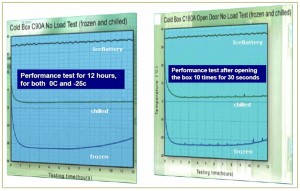

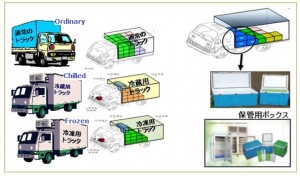

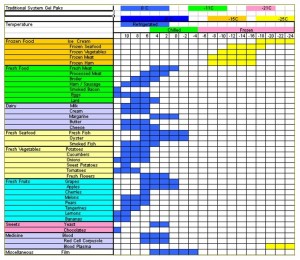

The IceBattery System (IBS) is a cold delivery system developed by a Japanese company Innovation Thru Energy (ITE) Co., Ltd. IBS would be a part of the next-generation cold chain logistics. Compared with the conventional system such as dry ice, IBS can control stable temperature for delivery (up to seventy two hours) and can maintain different temperatures as per the food requirement (temperature range between -25 and 25 degree Celsius). The plates of IceBattery are reusable for more than three years and reduce transportation cost. The coolant of IceBattery is a confidential material. According to ITE, the combination of coolant and water can maintain a constant temperature. Compared with dry ice, IBS cuts CO2 emissions by 20-25 percent.(Fig. 1) IBS keeps better constant temperature than the conventional frozen and chilled systems.(Fig. 2) IBS does not need frozen and chilled trucks for delivery.(Fig. 3) In Japan the total delivery cost can be reduced up to 50 percent without the use of freezer truck. Food has a various range of optimum temperatures to preserve. (Fig. 4) IBS can adapt the specification on the request of preserving temperature and delivery time. Since 2003, IBS has been used by the food delivery industry in Taiwan for Starbucks and Seven-Eleven. IBS can be used in the fish, air cargo, flower, military and other possible markets. In 2010, Japan Airline (JAL) decided to use IBS and started to offer cold chain logistics in air cargo market.(2) A company of JAL group, Logi-Rex Inc., developed a service with IBS. Qhai Service (cold logistics), Alfresa (drug delivery), Mitsubishi Chemical Medience (blood delivery) and Kinki Express (blood delivery) also use IBS services.

Figure 1. IceBattery System (source: Innovation Thru Energy Co., Ltd.)

Figure 2. IceBattery keeps temperature constant (source: Innovation Thru Energy Co., Ltd.)

Figure 3. Truck delivery by IceBattery (source: Innovation Thru Energy Co., Ltd.)

Figure 4. IceBattery covers a various range of optimum temperatures for food preservation (source: Innovation Thru Energy Co., Ltd.)

Shock absorbing packages for fruit and vegetables

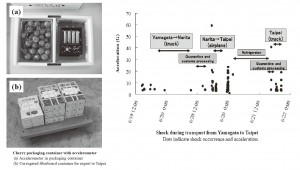

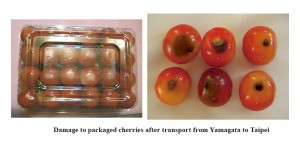

Dr. Yutaka Ishikawa of the National Food Research Institute has analyzed vibrations and shocks during fruit and vegetables transport and developed new shock absorbing packages. Vibration and shock during transport damages fruit and vegetables. Mechanical damage in transport, including abrasions and bruises, reduces the quality of these foods. In Japan the loss of fresh foods accounts for 17 percent for fruit and 10 percent for vegetables, during the transport and distribution.(4, 5) 1.4 million tons of vegetables and 1.2 million tons of fruit are wasted due to logistics in Japan. Ishikawa indicates that the loss of fruit and vegetables can be reduced by the way of 1) producing robust fruit and vegetables, 2) cold chain logistics, 3) shortening the delivery time, 4) packages enabling vapor control and gas environment, 5) shock absorbing packages to reduce damages in transport. (4) Ishikawa focuses on research and development of shock absorbing packages to reduce damages during transport, by way of economical and environmental approach. In his paper about vibration and shock analysis of fruit and vegetables transport, a case study of cherry transport from Yamagata in Japan to Taipei in Taiwan was investigated.(5) It was found that many cherries are damaged with loading and unloading at the airports, because of strong shocks. And there were more shocks during transport in Taiwan than Japan.(Fig. 5, 6) After many experiments against vibration and shock, Ishikawa developed a new shock absorbing package for cherries.(Fig. 7) Using this new package, no damage was detected during transport from Japan to Taiwan. A Japanese company Nippon Tokan Package Co., Ltd. has already produced it in a series of its ‘Fulltector’ product. It is still expensive to commercially use for the transport from Japan to Taiwan. It has also been designed for sending fruit by mail in an A4 letter package by Japan Post Co., Ltd. Prior to cherries; Ishikawa was involved in new packages for strawberries. Based on his research, some packages for strawberries are already commercialized by Japanese companies Oishi Sangyo and Nippon Tokan Package.

Figure 5. Cherry packaging container with accelerometer (left) and Shock during transport from Yamagata(Japan) to Taipei (Taiwan) (right)(source: National Research Institute)

Figure 6. Damage to packaged cherries after transport from Yamagata (Japan) to Taipei (Taiwan) (source: National Research Institute)

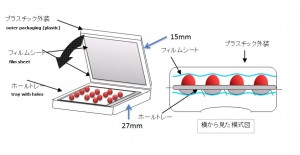

Figure 7. new shock absorbing package for cherries (source: National Research Institute)

Figure 8. New shock absorbing packages for strawberries (source: National Research Institute)

Prevention of sprouting potatoes

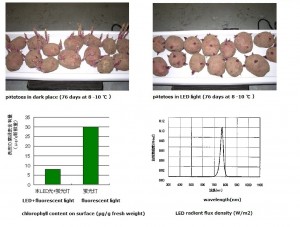

Potatoes can be preserved for a long period. But the quality of potatoes in storage deteriorates by sprouting. This contains the poisonous glyco-alkaloid. In Japan there is currently no chemical approved to use against the sprouting. Tajiri Machine Manufacturing Co., a manufacturer of warehouse facilities, and Hokkaido Electric Power Co. have developed a new potato preservation system using an infrared LED, which restrains potatoes from sprouting and greening.(6) Compared with potatoes in a dark place, those in the LED light were restrained from sprouting. Also compared with potatoes in fluorescent light, those in both the LED and fluorescent lights cut more than 70 percent of their chlorophyll content, which makes potatoes green.(Fig. 9) Regarding logistics, the use of the LED light allows potato warehouses to store at higher temperature, which makes the facility and operation costs lower. And it improves a working environment in warehouse in combination with fluorescent light, because it needs to store potatoes in the dark. This system has been already patented by Tajiri Machine and it is planning to implement the system in Japan.

Figure 9. Sprouting and green potatoes with or without infrared LED light (source: Tajiri Machine Manufacturing Co., Ltd.)

Non-destructive monitoring of meat quality

In Japan, there are 17 major poultry plants which process more than 30,000 tons of poultry per year, according to Japanese Agriculture Ministry. The sanitation monitoring of a processing plant or a processing line is directly related to food safety. It is carried out in several ways: visual inspection, swabbing for microbiological analysis or ATP bioluminescence. (7) At a meat processing plant, a more rapid and accurate detection system for microbial spoilage of meats is needed. University of Tokyo’s professor Seiichi Oshita and his group have developed a method of non-destructive evaluation of pork meat quality using fluorescence spectroscopy. They found that the fluorescence of tryptophan and NADPH (nicotinamide adenine dinucleotide phosphate) changes along with the growth of microorganisms and microbial spoilage on meat can be detected. This new optical sensing method will enable a real-time sanitation monitoring. It makes it easier to use than microbial analysis or ATP bioluminescence. Microbial analysis needs more than two days and ATP bioluminescence needs at least a few minutes for full detection by a skilled worker. Regarding logistics it will potentially influence the conditions of storage and distribution on meats in the near future. Oshita’s group will focus on further development including the high precision management of sanitation at the meat processing plant.

Cool TA-Q-BIN to deliver fresh Japanese foods

As a new international trend in Japan, this year All Nippon Airways (ANA) has started international refrigerator Cool-TA-Q-BIN service from Japan to Hong Kong on a trial basis. (8) With this service, Japanese foods such as crabs, beef and tangerine fruits can be delivered to customers in Hong Kong. TA-Q-BIN has recently started its international courier service to cities in Taiwan, Hong Kong, Shanghai, Singapore and Malaysia, in collaborations with ANA. It ensures the delivery of goods in two days through a twenty-four-hours operating ANA’s customs clearance at the distribution hub in Okinawa, a south island of Japan. The Cool-TA-Q-BIN is a new refrigerator service of TA-Q-BIN to deliver fresh Japanese foods.

Sources:

1) 2012 Logistics Survey Report, Japan Institute of logistics Systems (in Japanese).

2) Food Technology Forum, Tokyo 14 June 2013, Japanese Society of Agricultural Machinery (in Japanese).

3) Innovation Thru Energy Co., Ltd.

4) Evaluation of vibration and shock analysis of fruit and vegetables and its package technologies by Yutaka Ishikawa, National Food Research Institute, National Agriculture and Food Research Organization (in Japanese).

6) Tajiri Machine Manufacturing Co., Ltd. (in Japanese).

8) People in Asia will now be able to taste fresh Japanese food, thanks to TA-Q-BIN, ANI News.