Kikuo Hayakawa, NOST Tokyo

Origineel gepubliceerd op de site van Agentschap NL.

In grote, dichtbebouwde steden in Japan creëren files en verkeersongelukken grote problemen. Vanuit het oogpunt van logistiek management leiden deze problemen tot minder veilig en efficiënt goederenvervoer per vrachtauto en vertraging in de aflevering.

De Japanse overheid wil tegen 2020 de verkeerscongestie in vergelijking met die in 2010 met de helft terugbrengen.

Intelligente transportsystemen (ITS) spelen daarbij een belangrijke rol. De overheid heeft de laatste 30 jaar fors geïnvesteerd in ITS-gerelateerde infrastructuur. Met name ITS-diensten, zoals Vehicle Information and Communication Systems (VICS), worden nu veel gebruikt in autonavigatiesystemen, elektronische tolpoorten en ITS-Spot voor veiliger rijden. Verschillende Japanse ICT-bedrijven leveren hun ITS-gerelateerde diensten ook aan logistieke en vervoersbedrijven. Hierdoor is het mogelijk om vrachtauto’s automatisch en autonoom in een dichte kolonne (platooning) over de snelweg te laten rijden. Japan loopt voorop met de implementatie van dit systeem dat in 2020 definitief van start moet gaan.

Details

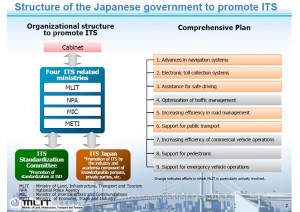

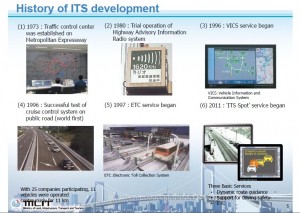

In Japan, traffic congestion time causes a loss of five billion hours a year. The 73,000 traffic accidents result in 4,411 fatalities in 2012. (1) The transport sector accounts for twenty percent of total amounts of CO2 emissions in Japan. The Japanese government has a target to halve the amount of traffic congestions by 2020, compared with 2010. In Japan, Intelligent Transport Systems (ITS) have played a major role to reduce traffic congestions. ITS is designed to integrate people, roads and vehicles in order to resolve road traffic problems such as congestion, accidents and environmental degradation.(2) Japan has promoted ITS technologies to reduce traffic congestions, resulting in improvements of traffic safety and fuel efficiency. Investments in ITS is supported by the Japanese Cabinet and four ministries (Fig. 1). Currently their nine comprehensive plans have been implemented. The industry’s association, ITS Japan, is the core player of industrial promotions of ITS in Japan. ITS Japan is organized by car and ICT companies in Japan in cooperation with local and central governments, universities, research institutes and associations. It has 250 members in total, including the Dutch TNO Automotive (Fig.2). ITS-related infrastructures have been financially supported by the government for thirty years(Fig.3). Vehicle Information and Communication System (VICS), Electric Toll Collection System (ETC) and ITS Spot are major governmental ITS services in Japan.

Figure 1. Structure of the Japanese government to promote ITS (source: Ministry of Land, Infrastructure, Transport and Tourism(MLIT))

Figure 2. History of ITS development in Japan (source: MLIT)

Figure 3. History of ITS development in Japan (source: MLIT)

VICS and ETC

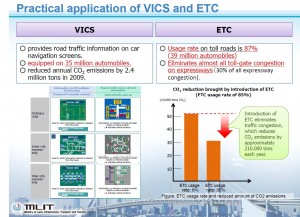

One of the ITS services, Vehicle Information and Communication System (VICS), has been active in Japan since 1996. VICS provides drivers with public road traffic information, collected from road operators and police control centers in Japan, with free of charge. Thirty five million units of VICS have been sold in Japan. VICS helps drivers to find an efficient route to their destination, resulting in the reduction of traffic congestion. VICS contributed a reduction of 2.4 million tons of CO2 emissions (Fig.4). In Japan, car navigation systems with VICS are very popular among truck drivers. Currently Toyota, Honda, Nissan and Pioneer especially provide their users with detailed traffic information based on their probe data. When the big disaster on March 11, 2011 occurred in Japan, many roads in the north east region of Japan were destroyed and there was no public traffic information from the region. However, probe data was useful. Thanks to an initiative by ITS Japan, within eight days after the disaster, drivers were able to get the data from either the car navigation systems in their cars or ITS Japan’s website via smartphones or personal computers etc. ITS Japan provided consolidated probe data compiled from Toyota, Honda, Nissan and Pioneer. (3) This information was useful for logistics operators with truck transportation carrying everyday goods effectively for refuges.

Electronic Toll Collection System (ETC) has been implemented on expressways since 1997. ETC allows drivers not to stop at toll-gates of highways. Prior to ETC, drivers had to stop once at the toll-gates, and it caused traffic congestions in front of the toll-gates. Already thirty nine millions of automobiles use ETC, accounting for eighty seven percent of all the automobiles in Japan. ETC has reduced thirty percent of traffic congestions with expressways, all of which occurred at the toll-gates (Fig.4).

Figure 4. Practical application of VICS and ETC (source: MLIT)

ITS Spot

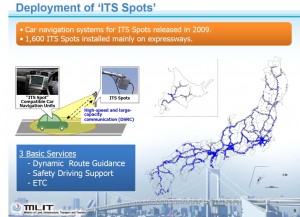

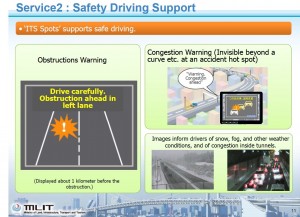

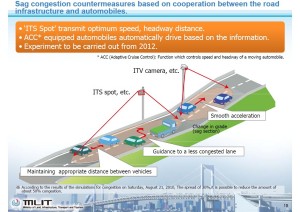

In 2011, ITS Spot service was started, enabling drivers to receive more dedicated traffic information to improve the quality of navigation systems within a city and traffic safety. ITS Spots communicate by a high-speed and large capacity communication DSRC (Dedicated Short Range Communication) with cars driving on roads (Fig.5). ETC uses DSRC to communicate with cars, which applied also for ITS Spot. 1600 ITS Spots are installed mainly on expressway in Japan. After released in 2009, totally ten millions of ITS Spot-compatible car navigation systems for automobiles were sold in Japan. For instance, with ITS Spot service, Drivers can receive an alert message in case a congestion occurred at an invisible area beyond a curve (Fig. 6). Since 2012 a project of sag congestion countermeasures has started with ITS Sport. (4) In Japan, sag congestions on expressways account for sixty percent of all congestions on expressways. Drivers tend to let their speed lower at upward slopes. The ongoing project aims to reduce sag congestions by making automobiles accelerate at upward slope. ITS Spot transmits an optimum speed and headway distance. ACC (Adaptive Cruise control) equipped automobiles to receive the information from ITS Spot and adapt them at upward slopes (Fig.7). To reduce traffic congestions, Honda has developed a new technology in cooperation with University of Tokyo’s professor Katsuhiro Nishinari, as described in my article before. (5 )

Figure 5. Deployment of ITS Spot (source: MLIT)

Figure 6. ITS Spot (source: MLIT)

Figure 7. ITS Spot (source: MLIT)

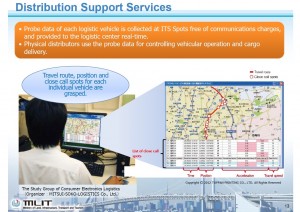

A Japanese logistics company Mitsui-Soko Logistics Co., is actively involved in a project of distribution support services using ITS Spot. In the project, logistics centers collect probe data of trucks based on ITS Spot services. The project is conducted by a consortium Hakata Island City Next-Generation Logistics Study Group, in Fukuoka City in cooperation with nine companies including Sharp and Fujitsu. It aims to green logistics to realize in an efficient handling of electric appliances by way of a shared warehouse and trucks. Actually, 40.6 percent of CO2 emissions, or 22.9 metric tons, was reduced due to the project. (6) This project received an Award of Excellent Green Logistics by the Japanese government in December 2012.

Figure 8. Distribution Support Services with ITS Spot (source: MLIT)

In Japan, ITS services are one of major factors to secure the efficiency of logistics. (7)

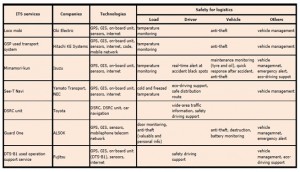

Several Japanese ICT companies and automakers provide their ITS-related services to improve the safety of logistics with truck transportation. Table 1 shows the ITS services provided by seven companies in the fields of ICT, automobiles and security service. ITS services from Toyota and Isuzu (truck manufacturer) aim to be provided for their corporate customers. Isuzu’s Mimamori-kun service enables a real-time vehicle management through interactive communications with GPS between vehicles and the office (Fig. 9). (8) The drivers do not need to register their deliveries. See-T Navi has been developed for Yamato Transport (delivery company) in cooperation with NEC (ICT company). See-T Navi has been launched in March 2010 in Japan. It makes drivers aware of the potential risks of their driving, and helps them drive safely. ALSOK, a Japanese major security service company, has developed its service to protect drivers and vehicles from thefts and accidents. The other four ICT companies (Oki Electric, Hitachi KE Systems and Fujitsu) have developed ITS services for not only large-sized truck transport companies, but also small or medium-sized companies which need inexpensive and simple specifications.

Table 1. ITS-related services for the safety of logistics (source: E. Masuda, H. Ono and Y. Yano, Ryutsu Keizai University)

Figure 9. ISUZU’s Mimamori-ku Online Serive (source: HINO)

Cooperative truck systems (platooning)

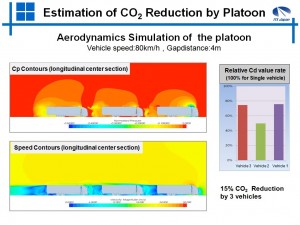

Cooperative truck systems (platooning) are based on a technology of cooperative adaptive cruise control (CACC), which optimizes the distance between trucks to avoid traffic congestions. In February 2013, an experiment of cooperative truck systems was successful in Japan. It was a platoon of three automated heavy trucks, driving at eighty kilometers per hour with a gap of only four meters (Fig.10). (9) This experiment was based on developments of a five-year governmental project, Energy ITS. More than seventeen organizations from academia, industry and research institutes joined the project. (10) It was funded through NEDO (New Energy and Industrial Technology Development Organization) with thirty three million euro in total. The lateral control of this project is based on lane marker detections by computer vision, and the longitudinal control is based on gap measurements by radars and lidars, and also the vehicle-to-vehicle communications based on DSRC. (11, 12) And this project indicates that it is possible to reduce energy by fifteen percent due to aerodynamic drag reductions (Fig. 11). According to ITS Japan, the developments of Energy ITS lead other three platooning projects in the world, such as SARTRE, PATH and GCDC.

Figure 10. Automated platoon (source: ITS Japan, JARI, NEDO)

Figure 11. Platoon of CO2 reduction by platoon (source: ITS Japan)

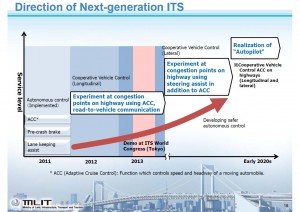

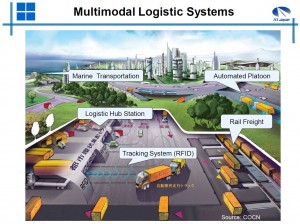

Japan’s platooning of Energy ITS will be demonstrated at the ITS World Congress 2013 in Tokyo on Oct 15-18. (13) ITS Japan indicates that traffic congestions will be possibly mitigated when more than thirty percent of automobiles on roads are equipped with the CACC technology. (3) In order to realize it, Japan focuses on further developing platooning. Japan aims to proceed with experiments at congestion points on highways using a steering assist in addition to ACC (lateral control) for the next years (Fig.12). Japan has a target to realize automatic driving on highways, ‘Autopilot’, using automobiles equipped with ACC (longitudinal and lateral) by the early 2020’s. Regarding logistics, the future automated platoons will possibly change the surrounding infrastructures including dedicated platoon lanes, logistics hub stations, marine transportations and rail freights (Fig. 13). In Tokyo, twenty millions passengers use public transportation such as trains and busses everyday. Especially Tokyo will need a new platform of multimodal logistics systems to realize a smooth transportation along with the future autopilot automobiles.

Figure 12. Next-generation ITS (source: MLIT)

Figure 13. Multimodal Logistics Systems (source: ITS Japan, COCN)

Currency:

1 euro = 132 yen (as of August 26, 2013)

Sources:

1) Duurzame mobiliteit en verkeersveiligheid, IA netwerk

2) ITS Initiatives in Japan, Ministry of Land, Infrastrucure, Transport and Tourism.

3) Resilient ITS, Government of Japan.

4) Report for NILIM sag congestions project in Japanese.

5) Honda develops technology to reduce traffic congestion, Japan.

6) Mitsui-Soko Logistics Receives an Award under the Excellent Green Logistics.

8) ISUZU Mimamori-kun Online Service.

9) NEDO Cooperative Adaptive Cruise Control System (video).

10) NEDO Energy ITS project (2008-2012).

12) Overview of platooning systems, ITS World Congress in Vienna 2012.