Kugako Sugimoto, NOST Tokyo

Originally published on the site of Agency NL

Biofilm has a unique feature (microbial communities living in a sticky matrix). Though biofilm has been recognized as unwanted objects, recent studies on biofilm suggest the use of biofilm in various fields. Such includes as glue, as nanofibers, for water quality improvement, for food production (alcohol), and for effective wastewater treatment. The key of successful application to the industry is understanding the biofilm. Study on biofilm for the industrial application to the industry has just started.

Details

Introduction

Biofilm is a slime you will find in the kitchen sink, shower room, or the swimming pool if you don’t clean them often.

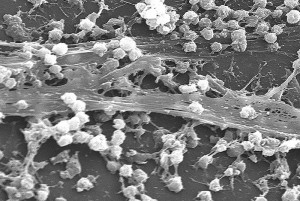

This is a community of microorganisms aggregating in an organic three-dimensional matrix attached to a surface (Fig. 1). Though it is said that Van Leeuwenhoek observed the biofilm, the term biofilm started to be used in the late ‘70s.

Recently, unique characteristics such as stickiness and a micro community of functional bacteria trigger the interests for industrial applications. Such application are for glues, supporting materials of cells in a reactor, wastewater treatment, and an enhancer of water quality in natural environments. To understand the application of biofilms, it is necessary to

know what a biofilm is.

Formation of biofilm

Formation of a biofilm consists of four to five phases. In the first phase, a free-living (unattached) microorganism attaches to a surface. This attachment attributes to Van der Waals’ forces. This attachment is reversible because Van der Waals’ forces are weak forces that occur between neutral molecules. During the second phase, cells anchor themselves to the surface more strongly using by microscopic appendages extending from the surface of the cells. One of such microscopic appendages is a pilus. In the third phase, a biofilm grows through cell division of anchored cells and recruitment of free-living organisms from the nearest environments. At the same time, cells release extracellular polysaccharide (EPS) and create a three-dimensional matrix. Then, the biofilm grows and reaches the climax such as a

lifecycle of a forest. When a biofilm cannot hold together as a colony, biofilm and residing cells disperse.

Community

In the matrix of a biofilm, there are high molecules and low molecules. High molecules are polysaccharide, polypeptides, and extracellular DNA. Low molecules are quorum-sensing signals (QSS), transporters such as autoinducers and compound lipids that lower surface tension of a liquid (bio surfactants). QSS recognizes population density and accumulates in a biofilm. As a result, the different gene expression from free-living bacteria is observed in bacteria in a biofilm because environmental influences on genes are different. EPS is one of the components of a biofilm. For Bacillus subtilis, commonly found bacterium, EPS is produced by an EPS gene cluster. Pseudomonas aeruginosa, another commonly found bacterium, produces polysaccharides consisting of mainly glucose, mannose, and galactose. In addition, extracellular DNA is accumulated in a biofilm. Therefore, horizontal gene transfer that genes were transferred rather than traditional reproduction might occur in a biofilm between microorganisms.

Bacterial nanofiber as nano material

Bacteria produce adhesive nanofibers to partially form a biofilm and use to attach themselves to a surface. Stickiness of this nanofiber is very strong. Research team of Department of Biology of Indiana University reported that the strength of nanofiber of bacteria, Caulobacter crescentus was 68 N/mm2. This is more than twice the strength of strong glues on the market. This nanofiber enable microorganisms to attach to the surface by conquering the energy

barrier between microorganisms and the surface. At the first stage of the development of biofilm, Van der Waals’ force is the main force to attach the surface. However, there is also a repulsive force between a surface and a bacterium.

In the water, a bacterium is negatively charged because carboxyl groups and phosphate groups on the cell surface are dissociated. The surface of biofilm is also negatively charged in the water. Repulsion between negatively charged surface and negatively charged bacteria is an energy barrier for bacteria to attach the surface. A smaller size than bacteria becomes important to go through the energy barrier.

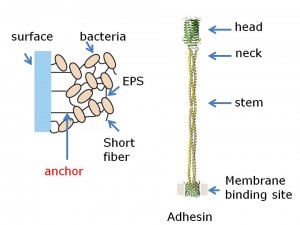

In an environment with the ionic strength where biofilm develops, a low energy barrier between microorganisms and a surface exists. Bacteria first approach as close as possible to the surface by Brownian motion or movement of cellular structure (e.g. flagella, cilia) and contacts reversely. Then much smaller EPS and bacterial nanofiber than bacterium itself go through the energy barrier and attach to the surface where Van der Waals’ force is strong enough to keep attaching the microorganisms to the surface. Professor Hori of School of Engineering at Nagoya University has researched bacterial nanofiber and identified two types of fibers on the cell surface of Acinetobacter sp. Tol 5. Cells

used these nanofibers to attach themselves to the surface. One type of fiber is a linear fiber and interacts with the surface at the tip of the fiber like an adhesive anchor (Fig.2). In the research, these filamentous and long bacterial nanofiber make it possible to interact with the surface beyond the distance of a few hundred nm. It appeared to be possible to control the amount of expression of these fibers. Toxicity to the human body is not reported. Anchor type of nanofiber with high adhesive quality and small size would be a candidate for a new material to work in an aquatic environment as well as in a human body. The technology for large scale production of these adhesive anchor type nanofibers by bacteria can support the use of such materials in surgery.

Fig. 2 Anchor and Adhesin (From Prof. Hori of Nagoya University)

Water quality improvement

Professor Hori also conducted the research on the ability of biofilm to improve the water quality in natural environments. In Japan, carbon fibers in ponds, lakes, and coastal environment are installed in many places because they have improved water quality by removing organics in the eutrophic waters. In addition, biofilm developed on the carbon fibers provides food for microorganism in the water. However, it has not been known why carbon fibers rather than other synthetic fibers can efficiently develop biofilm. Carbon fiber is made mostly of carbon atoms and is less negatively charged compared to other synthetic fibers. Therefore the negatively charged microorganisms are free from strong impulsion with carbon fibers compared to other types of fibers. Intermolecular forces were also stronger between

bacteria and carbon fiber in the water compared to other materials. Environmentally important bacteria such as nitrifying bacteria to convert ammonium to nitrate and nitrite also attached to the carbon fibers. Utilization of nitrifying bacteria may be applied to the more heavily polluted water such as wastewater treatment. This research was performed in close cooperation with Japanese company, Teijin.

Waste water treatment

Anammox is anaerobic ammonium oxidation to convert nitrite and ammonium directly into dinitrogen gas. This reaction was reported in 1999 and became a trademarked name for the anammox-based ammonium removal technology developed by the Delft University of Technology. Removal of nitrogen is one of key issue for wastewater treatment to prevent eutrophication of water in the discharged area. Dutch company, Paques is a front runner of this water treatment system with anammox reaction and already operates several facilities. Faculty of Engineering and Graduate School of Environmental Science & Faculty of Environmental Earth Science of Hokkaido University, is also designing the microbial community in biofilms including anammox bacteria for waste water treatment. The design includes spatial

arrangement of microorganisms and community composition including anammox bacteria. The research team uses a different strain (Candidatus Brocadia sinica) than the one Paques uses (Candidatus Kuenenia stuttgartiensis). Creating a biofilm with the right communities of organisms and a right arrangement according to the design, may lead to effective treatment with less energy consumption and byproducts.

Alcohol production

The College of Bioresource Sciences of Nihon University tested a complex biofilm with selected bacterial strains to produce alcohol. The systems in a small scale and a larger scale showed steady production of alcohol. The system did not require high maintenance because essential bacterial community stayed in the system due to the strong attachment through a complex adhesive biofilm. The idea for a complex biofilm came from the observation of the rice vinegar produced in a traditional way. Rice vinegar is produced in a pot without almost any maintenance. Saccharification (conversion from starch to sugar), anaerobic alcohol fermentation, and aerobic acetic fermentation occur in a pot. The formation of biofilm seems to contribute to fermentation. In the research, lactic acid bacterium (Lactobacillus lactis) and yeasts were obtained from fermenting mash. They were co-cultured and developed a thick complex biofilm. Lactic acid was dominant at the bottom of the complex biofilm. The aggregates of a mixture of yeasts and lactic acid bacteria were found above the bottom layer of the biofilm. The complex biofilm in a pot seems to stimulate the transformation of glucose to ethanol and lactic acid. In the small-scale experiment, cellulose beads with a complex biofilm were set in a reactor for alcohol fermentation. Yeast Peptone Dextrose (YPD) with 10 percent of glucose was applied and incubated at 30 degrees Celsius. Operations were repeated for ten times every 24 hours. The production rates of alcohol were almost the same when only yeast was used for one time operation. The production of lactic acid was low and did not bother the production of alcohol. In the scaled-up experiment using a bioreactor with a complex biofilm also produced steady

production of alcohol. Co-culturing of lactic acid bacteria and yeasts seems to allow development of a thick biofilm that holds bacteria very strongly to the system. On the other hand, the culturing only yeast does not develop a thick biofilm to hold yeasts inside the reactor. Yeast easily leaves the reaction system. The strong attachment of yeast to a thick complex biofilm reduces the cost and maintenance procedures of alcohol production.

Conclusion

Biofilms are considered a nuisance because they clog pipes, cause infections, and are gooey. However, biofilm can play an important role in natural environments and industrial facilities. Biofilm is used for improving water quality in natural environment without using chemicals. Controlling of fixation of bacteria to the surface may contribute to waste water treatment, fermentation of food, and biomass energy. Adhesive nanofiber produced by bacteria also can

be used as reversible and strong glue in an aquatic environment. Biofilm is no longer unwanted thing. It is a new material that should be studied.

Source:

1. Wikipedia, biofilm

2. Wikipedia, EPS

3. Functional bacterial nanofiber of attached microorganisms

4. Ethanol Fermentation by complex biofilm of two strains

5. Development of high efficient bio-treatment technology by designing of microbial

community

6. Wikipedia, quorum sensing