Kugako Sugimoto, NOST Tokyo

Originally published on the site of NL Agency.

Japan is searching and developing natural resources under the sea. One of the goals for natural resource development is to commercialize sea-floor hydrothermal deposits in exclusive economic zones (EEZ) by 2018 – 2019. This is done to secure an alternative supply of minor metals and rare earths. Japan is trying to become more independent from imported natural resources because of a growing concern for ‘resource nationalism’ and increasing prices. Preliminary research to grasp distribution, quantities and location of natural resources is necessary before a development project can be launched. To increase the energy payback ratio on natural resource development, new technologies are being studied.

Introduction

High-technology industries currently use minor metals and rare earths as essential components of their products. For example, the Netherlands is a huge importer of cemented carbide, made of minor metals such as tungsten (wolfram, W) and tantalum (Ta). 73 % of all cemented carbide exported to EU, amounting to a worth of 520,000,000 U.S. dollars, went to the Netherlands in 2009. W is used, for example, for miniature drills to make tiny holes for use in miniaturized electric devices. Ta is used in fuel cell, solar batteries and semiconductors. Japan supplies 71% of the EU imports of cemented carbide. Although Japan exports some processed minor metals, it also highly depends on importing minor metals and rare earths.

Importing minor metals and rare earths from a single source, China, is not good for stable economic growth. This goes especially for high tech industries because suppliers’ policies can have a huge impact on the development and even existence of these industries. China for instance controls the export of W by imposing tax, limiting the export volume and setting minimum export prizes. Negotiating and appealing to the World Trade Organization (WTO) are two of the directions to solve this problem. Searching for alternative sources is another direction.

Japan started to search for natural resources, including minor metals and rare earths, under the ocean in their EEZ to diversify the supply of natural resources. This activity is one of the targeted areas of the national plans on clever use of marine resources endorsed by the Japanese Diet in 2008. Finding and estimating commercially viable proven reserves of hydrothermal deposits from the vast sea floors is a priority to conduct the plan successfully. New maritime technologies are invented to guarantee success.

Sea-floor hydrothermal deposit

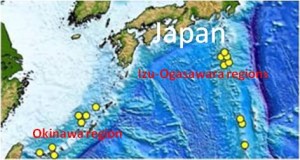

The location of sea-floor hydrothermal deposits is associated with the volcanic activity in for instance the oceanic ridge. These deposits are formed in several steps. First, seawater seeps through under the oceanic crust and it is heated by magma. Then various types of metals in the oceanic crust dissolve into the heated seawater (270 – 350 °C ). When this heated seawater is spewed into the bottom of the ocean again through ‘chimneys’, it is rapidly cooled by the surrounding cold seawater. The metals are then deposited on the sea floor. Sea-floor hydrothermal deposits contain typically zinc (Zn), copper (Cu), lead (Pb), gold (Au), and silver (Ag). The ratio of deposited metals depends on the geological characteristics of the deposit site. Sea-floor hydrothermal deposit sites, discovered within the EEZ of Japan by 2004, were mainly located in the Izu-Ogasawara regions and in the Okinawa region (Fig. 1). These deposits were characterized by black ore with various valuable elements such as zinc sulfide (ZnS), lead sulfide (PbS) and Chalcopyrite (CuFeS2). Vertically, they are located in relatively shallow water, from 700 to 1,600 meters deep. This is shallow compared to other natural resources such as manganese nodules, typically found at 4,000 to 6,000 meters depth.

Fig. 1. Locations of sea-floor hydrothermal deposits in EEZ of Japan (MEXT)

Steps forward

To commercialize sea-floor hydrothermal deposits in 2018 – 2019 is a goal of the project “Basic Plan on Ocean Policy” endorsed by the Japanese government in 2008. Two major steps are needed before the development of natural resources can take place. The first step is investigation in the field and the next step is assessment of the data obtained in the field in the first step.

During the field investigation large areas are roughly covered to find the candidates for development sites. Sonar is primary used as well as gravitational prospecting, magnetic force and seismic phase to get seabed information. Then sediment samples are collected to be analyzed in a laboratory. If necessary, sample drilling is conducted to obtain sediment samples. After selecting optimal candidates based on availability of resources, assessment will be conducted from the economical, environmental, and technical points of view. The volume is generally a key factor to determine whether a development project will be launched. Larger proven and commercially viable reserves bring a higher energy payback ratio because of relatively reduced extraction costs.

In Japan, none of the commercial developments of sea-floor hydrothermal deposits has started yet. Currently, effective ways to select the optimal development sites are investigated. Technology to actually retrieve sea-floor hydrothermal deposits has not yet been developed. In 2012, quite substantial government funds, up to 60,000,000 yen for one research theme*, were implemented for effective technologies to grasp the location, volume, and quality of sea-floor hydrothermal deposits. However, commercialization of mining sites is reportedly delayed because on-site experiments of related technologies were limited, mostly due to the unavailability of research vessels (Nikkei June, 5, 2012). Nonetheless, researchers are striving to conquer the difficulties.

There are several maritime technologies as options for sea-floor hydrothermal deposit development, being invented and awaiting commercial use.

Wide-range Survey Technology

1) 3D image of the sea floor

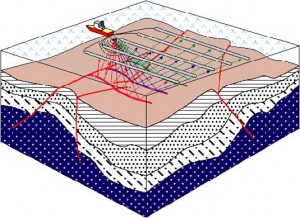

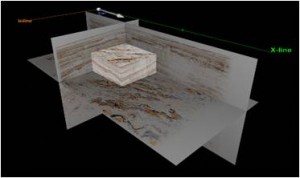

Advanced three dimensional seismic prospecting describes depths of layers and structures in the sea floor. Seismic prospecting uses air guns to cause pressure waves in the water. The receivers detect the reflection of these waves after hitting the layers in the sea floor. The differences between several received waves indicate the different characteristics of the sea floor. This helps to create 3D pictures of the layers in the sea floor. For a clear 3D picture, a research vessel tags multiple reception cables and detects reflected waves in multiple directions by orchestrating the positions of receivers and the air gun (Fig. 2). By removing noise from the data and by other manipulations eventually 3D images of the sea floor are created (Fig. 3).

Fig. 2. Image of 3D geophysical prospecting (tows multiple cables) (JOGMEC)

Fig. 3. 3D images of the sea-floor (JOGMEC)

2) The use of Hg and its isotopes

Another technology to detect sea-floor hydrothermal deposits uses an mercury (Hg) detector. Mercury is emitted from sea-floor hydrothermal deposits to the surrounding area, which can be a clue to locate the sea-floor hydrothermal deposits. Hg maps suggesting the existence of sea-floor hydrothermal deposits can be created by measuring the concentration of Hg in water samples collected in a wide area. At the same time, analyzing the ratio of isotopic Hg in sulfide provides the information of characteristics (new or old) of the sea-floor hydrothermal deposit. Only old and inactive areas would be candidates for development, because active and newly created hydrothermal deposits are usually associated with rare ecosystems on earth with potentially valuable chemicals or genes. These should not be disturbed by exploitation. Prof. Katsumi Marumo of the University of Toyama is one of leaders of this project.

Autonomous Underwater Vehicle (AUV) and Robot Technology

1) Yume-iruka, AUV

An AUV is used to get information from a large area. Yume-iruka, Japanese for dream dolphin is an AUV that is created by JAMSTEC. It is able to move at two to three knots and searches for natural resources (Fig 4). Yume-iruka is five meters long and is able to dive to 3,000 meters. It has panels to stabilize its body on both tail and head, which always enables Yume-iruka to point a sonar to the object, which is the sea floor. It can move along with bumpy sea floors and detects sediment surfaces up to thirty meters below itself. Yume-iruka is also able to sense boiling seawater, a typical signature of hydrothermal activities. The development costs were about 8,000,000 euro.

Fig. 4. Yume-iruka produced by JAMSTEC (Sankei)

2) UnRE#2, marine robot

After wide-range search for natural resources, grasping the detailed conditions of candidate development sites is essential. JAMSTEC is developing robots that obtain the detailed environmental information such as the pH and CO2 concentration very close to the objects. UnRE#2, one of the robots, is able to move at 0.5 to one knot and to move just above two meters from the bottom of the ocean (Fig. 5). Its load is a stereo-vision camera that is able to measure distance and three dimensional positions. In addition, it has a manipulator to work at the bottom of the sea. Researchers can control UnRE#2 from a research vessel.

Fig. 5. Created image of marine robots, UnRE#2 (JAMSTEC)

On-Site Analysis Technology

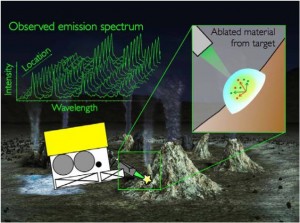

1)Laser induced breakdown spectroscopy (LIBS)

Currently, drilling the sea floor is a mainstream method to confirm sea-floor hydrothermal deposits on and under the sea floor surface. It takes enormous amounts of time and budget to extract and analyze samples to establish the volume of a deposit. Therefore there are technologies under development to establish the size of sea-floor hydrothermal deposits on and under the sea floor without drilling.

One research team of the Institute of Industrial Science at the University of Tokyo, is developing a technology of on-site analysis of sediment samples at a depth of up to 3,000 meters under high pressure. They use LIBS which shoots a strong laser pulse to the objects and creates plasma (Fig. 6). By analyzing these plasmas with a spectro-photometer, it becomes possible to detect what elements the object contains. It analyzes elements both in solids and liquids. This LIBS will be loaded on an AUV and create a map of the distribution of sea-floor hydrothermal deposits. This quick analysis provides information, which can be incorporated into on-going research plans and schedules at low cost. Optimal conditions to beam lasers and to detect the emitted plasmas under high pressure need to be studied further. In addition, miniaturization of the device is also requested to be loaded on an AUV.

Fig. 6. images of LIBS and analysis on the site (MEXT)

Conclusion

Commercialization of sea-floor hydrothermal deposits seems to be a great opportunity: economically for the private sector, scientifically for researchers, and politically for the Japanese government. However, the goal of commercialization is still far away. The quantities of sea-floor hydrothermal deposits that were already discovered are still not understood correctly. Before commercialization, several steps will have to still be worked out, such as large area searching, spot searching, environmental/economical/technical assessments, extraction and refining. All these steps require adequate devices, including computer models to predict the environmental impact as a result of the development of sea-floor hydrothermal deposits. Although this goal is still far away, related technologies already produced and being development in projects are definitely useful, even for other purposes. Realization and implementation of these maritime devices are eagerly awaited.

Sources

2) JOGMEC: http://www.jogmec.go.jp/

3) JOGMEC: http://www.jogmec.go.jp/

4) MSN Sankei News: http://sankei.jp.msn.com/science/news/120405/scn12040520550003-n1.htm

5) JAMSTEC: http://www.jamstec.go.jp/j/

6) MEXT: http://www.mext.go.jp/b_menu/boshu/detail/__icsFiles/afieldfile/2012/04/11/1319677_1.pdf

* http://www.mext.go.jp/b_menu/boshu/detail/__icsFiles/afieldfile/2012/04/11/1319677_1.pdf