Kikuo Hayakawa, NOST Tokyo

Originally published on the site of NL Agency

Summary

Currently, many smart grid projects are running or planned worldwide. These aim at controlling the electricity supply more efficiently and more stably in a new power network system. In Japan, especially superconductivity technology development projects are carried out to contribute to the future smart grid. Japanese cable makers such as Sumitomo Electric and Furukawa Electric are leading in the production of high-temperature superconducting (HTS) power cables. The world’s largest electric current and highest voltage superconductivity proving tests have been started this year. Big cities such as Tokyo will be expected to introduce the HTS power cables to reduce transport losses and to meet the increased electricity demand in the near future. Superconducting devices, HTS power cables, Superconducting Magnetic Energy Storage (SMES) and flywheels are the focus of new developments in cooperations between companies, universities and research institutes, funded by the Japanese research and development funding organization New Energy and Industrial Technology Development Organization (NEDO).

Details

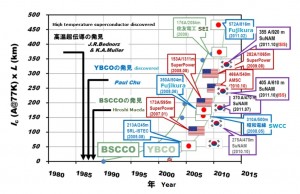

In 2011 the centennial anniversary was held for the discovery of superconductivity in 1911 by Dutch physicist Prof. Heike Kamerlingh Onnes. 25 years ago high temperature superconductivity was discovered by IBM employees Bednorz and Muller using ceramics. Since then research and development have been focused on high temperature superconductivity. Superconductor projects in Japan have been described already in an article in 2010.(1) Recent developments on high temperature superconducting (HTS) wires have been reported in the US, Japan and Korea (fig. 1).(2) The US company Superpower was acquired by Furukawa Electric in 2012. In Japan, Sumitomo Electric (SEI), Fujikura, SWCC and Furukawa Electric are leading the development of HTS power cables. Currently, the Japanese cable companies are involved in some HTS projects in the world by supplying HTS cables. In Japan transport loss of electricity adds up to about five percent in the trajectory from the power plant to the end user. This amounted to 977 billion kWh in 2010, which equals the electricity production of several nuclear power plants. The development of HTS power cables is expected to contribute to the reduction of transport loss and to the new smart grid in the future.

Fig. 1. Progress of high-temperature superconducting wires (source: ISTEC)

The largest electric current and highest voltage proving tests

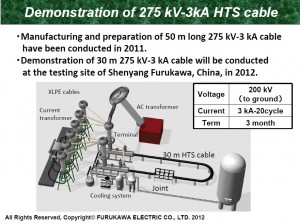

The Yokohama HTS cable project was launched in 2007 (fig. 2).(3) The seven years project was joined by Sumitomo Electric (SEI), Tokyo Electric Co. (TEPCO) and Maekawa and was funded by NEDO. The applied HTS cable is made of Dynamically Innovative Bi-Sr-Ca-Cu-O (DI-BSCCO) produced by Sumitomo Electric. TEPCO is the major power company in the Tokyo region and end user of the cable. Maekawa is involved in cooling systems. The long term test will start in November 2012 and will connect to an actual power grid in Yokohama near Tokyo. The project aims to verify the reliability and stability of the condition of the 66kV-3kA cable with a length of 250 meters. In the Tokyo region a total of four hundred kilometers of underground power cable has been installed. Total transport losses amount to 40 MW, caused by the production of heat. It is estimated that about half of the current losses can be recuperated by using HTS cables. The other proving test starts in 2012 by Furukawa Electric with a 275kV-3kV HTS cable based on Y-Ba-Cu-O (YBCO). This is the highest voltage test with HTS cable ever carries out (fig. 3). This project is also funded by NEDO. The test will run for three months. It will however be possible to extend this term, according to Furukawa Electric.

Fig. 2. Yokohama HTS cable project (source: NEDO)

Fig. 3. Demonstration of 275kV-3kA HTC cable ( source: NEDO, Furukawa Electric)

Superconducting device projects

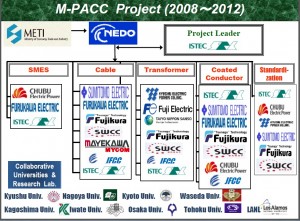

NEDO has funded the development of superconducting devices, including the above mentioned HTS cables, through its M-PACC project. It will be finished in 2012 (fig. 4-5). SMES, HTS cable, transformers and coated conductors based on YBCO are the focus of the developments in cooperation with many companies, universities and research institutes.

Fig. 4. NEDO’s M-PACC project (source: NEDO)

Fig. 5. R&D themes and goal of M-PACC project (source: NEDO)

HTS developments for smart grids

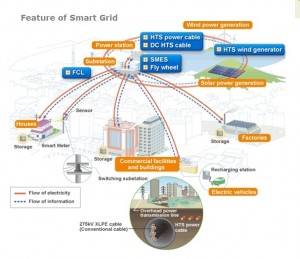

Currently many smart grids in the world are running specifically to test HTS cables. One of the main reasons for this is that the installation costs of HTS power cables cooled with liquefied nitrogen are still too high to replace the existing copper cables. The other reason is that real life tests are necessary to come to practical application. However, Japan foresees increasing demand for HTS devices for operational smart grids in the near future. The HTS devices in smart grids are HTS power cables (AC and DC), fault current limiters (FCL), HTS wind generation, SMES and Fly wheels (fig. 6).

Fig. 6. Feature of a smart grid (source: Furukawa Electric)

HTS power cables are expected to be installed, to begin with, in big cities such as Tokyo rather than in rural districts. In big cities the elimination of distribution losses is more worthwhile. The introduction of new HTS power cables, in addition to current tests, will contribute to a more efficient smart grid in the near future. FCLs will prevent short circuiting from accidents. These are essential devices in a smart grid to maintain the reliability of currents from renewable power sources. The development of FCLs is led by European companies such as Nexans. In Japan, Toshiba and Fuji Electric are developing FCLs with funding from NEDO. SMES and flywheels are both electric power storage devices. SMES is expected to efficiently store the surplus electric supply generated during the night time. Currently surplus current is used to pump up water and to drive electricity generating turbines with that water when the electricity demand reaches peaks. A 2GJ SMES will be developed by Chubu Electric, Furukawa Electric and ISTEC (4). The development will be funded through the above mentioned M-PACC project.

The flywheel storage system has been developed by US and European companies to store electricity for many applications. As yet a 20MW flywheel without HTS system has been installed in an actual grid in New York and a 26.5MW one Okinawa, Japan (5). In Japan the HTS flywheel system is being developed by the Railway Technical Research Institute (RTRI) (6), JR Central and Hitachi. In 2012 RTRI has started the HTS flywheel project funded by NEDO. It aims to develop and achieve a 300kWh flywheel system in 2015, connecting to a 1MW PV panel system in Yamanashi. International standardization of superconductivity is going on in ISO. Japan actively contributes to the working groups in ISO (7).

Source

(1) Supergeleidingsprojecten besparen energie in Japan

(2) ISTEC – Web 21, 2012 Summer: Development of superconductivity wire application technology

(3) High-Temperature Superconducting Cable Demonstration Project

(4) ISTEC (International Superconductivity Technology Center)

(5) Mizuho Industry Focus (in Japanese)

(6) Study of a High-temperature Superconducting Magnetic Bearing for Flywheel

(7) SEI TECHNICAL REVIEW (international standardizaiton activities for superconductivity)